PLANT MACHINERY

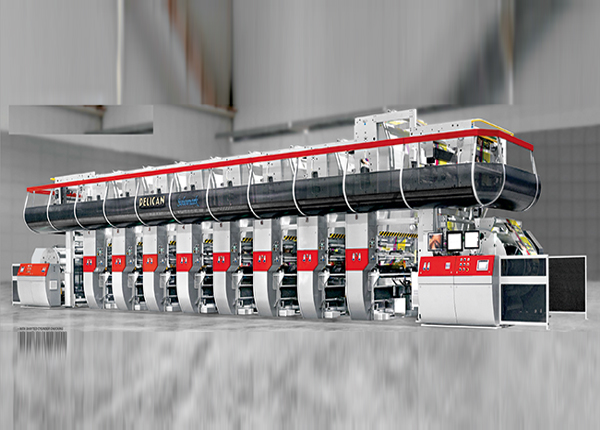

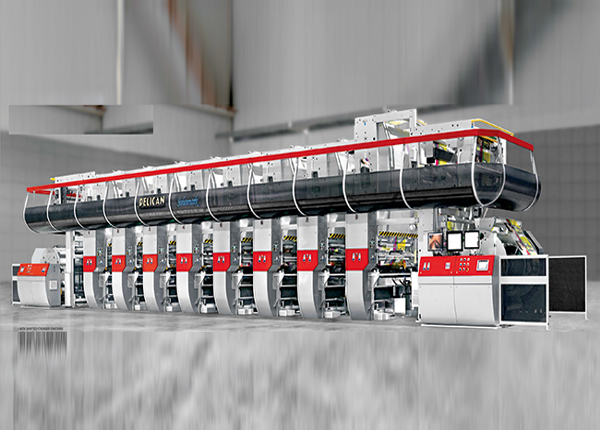

1- PELICAN SOLOMARK 8 COLOUR ROTO GRAVURE PRINTING MACHINE

-

MACHINE SPECIFICATION AND PRODUCTION DETAILS:-

We have Pelican 8 Color Roto Gravure Printing Machine with speed 200 mpm.This is auto machine, And monthly maximum production approx 70 ton to 90 ton. And Yearly Printing Production Turn Over 800-900 ton. Approximately.

2- PELICAN SOLVENT- LESS /LAMINATOR(SOLOLAM PLUS ) LAMINATION MACHINE

-

We have Pelican solvent Free Machine with speed 350 mpm.This is auto machine, Very Low energy Consumptiom,fast job change over and Unique Service Support , Monthly Production of our Pelican machine 300-360 ton. And yearly laminate Production Turn Over 3600 to 4000 ton Approx.

1-servo control system and master control panel

2- frame structure, adhesive metering system and full auto machine.

3-shaft less Unwinders & Rewinder group.

Pelican range of converting developed to archive high standard in flexible packaging solutions. Laminate substrates;- BOPP,PP CAST FILM,LDPE/HDPE/VARIOUS COEX ,NYLON CAST .PET BOPA,PAPER ETC .

3- PELICAN SOLOSLIT MACHINE MAXIMUM SPEED 500 MPM

-

Our Pelican machine slits material with proper quality with a speed of 500 mpm.Any types of material can slitt of this machine.its an very high performance this Machine. Monthly Production Maximum 200 ton to 250 ton

4-WINDSOR 5 LAYER PLANT POD MACHINE

-

This is windsor IBC POD Machine with fix position Air cooling ring (PLAST CONTROL Gmbh Germany make ).Maximum output up to 550 kg/hr and maximum film width up to 2550 mm.The unit capacity range die size 600 mm.Monthly Production Maximum 360 ton to 400 ton. And yearly Production Turn Over 4300 to 4800 ton

1-Maximum layer ratio (1:2:4:2:1).

2-Thin skin and sub skin layer with thick core.

3-Introduction of specific functionalities in discrete layers.

4-Increased flexibility through additional layer thickness combinations.

5-Exploration of Synergistic material/ layering effect.

6- Higher output by using layers of high melt strength materials.

7-Enhancement of mechanical property of the film.

8-Better puncher resistance property.

9-possibility of down gauging (can get more yield).

10-Reduced usage of MLLDPE.

11-Auto Profile thickness Plast control System.

12-High Output machine.

5- KABRA 3 LAYER PLANT (KET)

-

The Kabra OBC (Kabra ExtrusionTechnik) Machine with fix position Air cooling ring Maximum output up to 110 kg/hrs. and maximum film width up to 1050mm The unit capacity range die size 250 mm and Screw Dia meter Barrier 3*47 mm L and D Ratio 261 Main Drive 3*15(AC)(Kw). Monthly Production Maximum 75 to 80 ton. And yearly Production Turn Over 900 to 960 ton.

6- C- TRIVEDI SLITTING MACHINE ( MAXIMUM SIZE 2550 MM)

-

C-TRIVEDI Slitt machine maximum speed 250 mpm. And maximum Monthly production 180 to 220 ton.

7- PARAMOUNT PRINTOTECH SLITT MACHINE (MAXIMUM SIZE 1100 MM)

-

Paramount Printotech Slitt machine maximum speed 150 mpm. And maximum Monthly production 60 to 100 ton.

8- SHREE VINAYAK PACK MACHINE

-

This is Shree Vinayak Pouching machine .maximum Monthly production 35 to 45 ton. Maximum speed 200 mpm.

9- XL POUCH MACHINE (PLASTIC BAG MAKING MACHINE )

-

This is XL Pouching machine .maximum Monthly production 25 to 35 ton. Maximum speed 160 mpm